Kenyelletso ea Sehlahisoa

1.Mohala oa tlhahiso ea liroboto oa aluminium o ikatisang ka botlalo ke oa ho etsa liphanele tse tloaelehileng tsa aluminium.

2.Mohala oa othomathike o kenyelletsang ho kenya liroboto, ho itšeha, ho phunya, CNC slots milling, Rib's end milling (ho ikhethela), welding ea seporo sa mahlakoreng, stiffeners robotic welding, ho otlolla, konkreite holim'a buffing, ho laolla le ho theola liroboto, khatiso ea laser bar code ke boikhethelo.

3.Mohala oohle oa likoloi o na le maemo a phahameng a feto-fetohang bakeng sa tlhahiso e fapaneng ea liphanele tse tloaelehileng.Ho fapanyetsana pakeng tsa liphanele tse fapaneng ho bonolo haholo ebile ho potlakile ka lebelo hape.

4.Bakeng sa karolo ea ho kenya, opereishene e hloka feela ho kenya lisebelisoa tse tala ho transverse conveyor ka forklift, joale letsoho la robotiki le tla nka profil ka bo eona ebe le e jarisa ho conveyor ea karolo ea ho itšeha.

5.Karolo ea ho itšeha e nang le pokello ea lerōle la leholiotsoana le setsi sa ho tlosa litšila.

6.Mohala oa likoloi o na le likarolo tse peli tsa 3 metres punching, karolo ka 'ngoe ea ho phunya e ka otla Max.Ke masoba ka nako e ts'oanang, manipulator e laoloang ke CNC e ne e sebelisetsoa ho beha mohlala oa likoti tsa ho phunya, tse nang le ts'ebetso e phahameng le maemo a phahameng a feto-fetohang bakeng sa lisebelisoa tse fapaneng le ho netefatsa ts'ebetso e ntle ka ho fetisisa.

7.The ho sila karolo ka sila slots ka mahlakoreng a mabeli ka nako e le 'ngoe, lehlakoreng le leng le a hlomelloa le 3 CNC laoloa ho siloa lihlooho, tenyetsehang bakeng sa tlhokahalo e fapaneng slots siloa.

8.Mohala oa koloi o nang le matsoho a 2 a robotiki bakeng sa welding ea mahlakoreng a mabeli a mahlakoreng a mabeli, opereishene e hloka feela ho kenya litšepe tse ngata ka har'a sets'oants'o, manipulator e tla nka seporo se lehlakoreng ebe e e beha qetellong, ebe letsoho la roboti le tla. etsa ka tsela e iketsang welding.Karolo e 'ngoe le e 'ngoe e na le liteishene tse peli tse bapileng tsa seporo.

9.Mohala oa koloi o nang le matsoho a liroboto tse 6 ka lihlopha tse 3 tsa liteishene tsa welding bakeng sa stiffeners welding, opareitara e hloka feela ho kenya li-stiffeners tse ngata ka har'a sets'oants'o, manipulator e tla nka sehatelli ka bo eona ebe e e kenya ka har'a phanele sebakeng se nepahetseng. matsoho a mabeli a roboto a tla iketsetsa welding.

10.Ka mor'a liporo tsa mahlakoreng le li-stiffeners welding, phanele e tla fetoloa ebe e fepa karolong e otlolohileng le karolo ea buffing, ka mor'a ho phunya, phanele e tla fetoloa bakeng sa ho laolla letsoho la robotiki le ho bokella.

11.Bolelele ba thepa e tala: 6000mm kapa 7300mm.

12.Raw thepa bophara mefuta e fapaneng: 250 ~ 600mm.

13.Bolelele ba lihlahisoa bo felile: 600 ~ 3000mm.

Litlhaloso tsa 14.Customized lia amoheleha.

Lintlha tsa Sehlahisoa

-

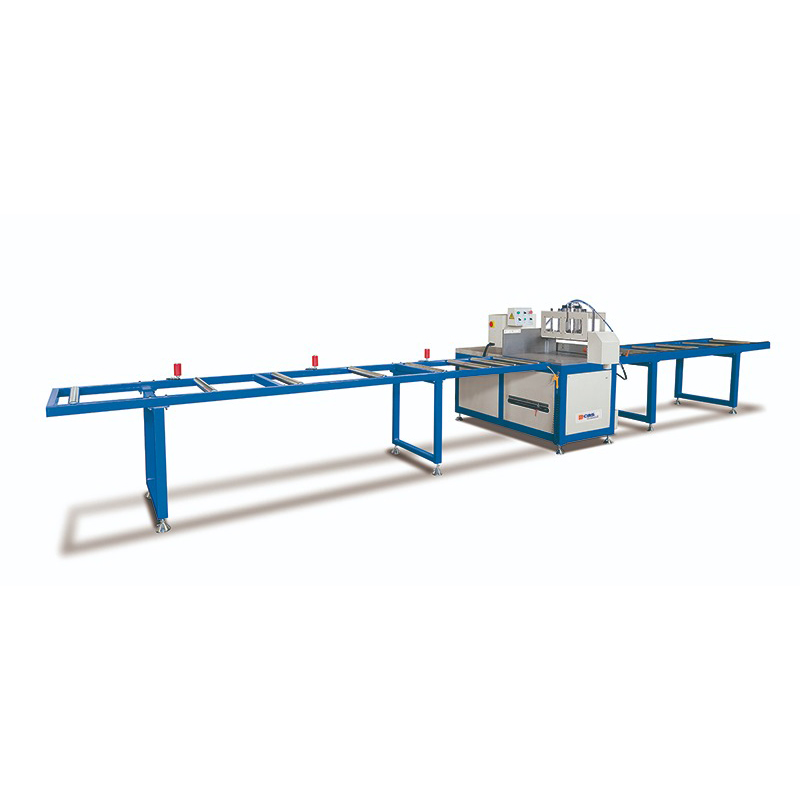

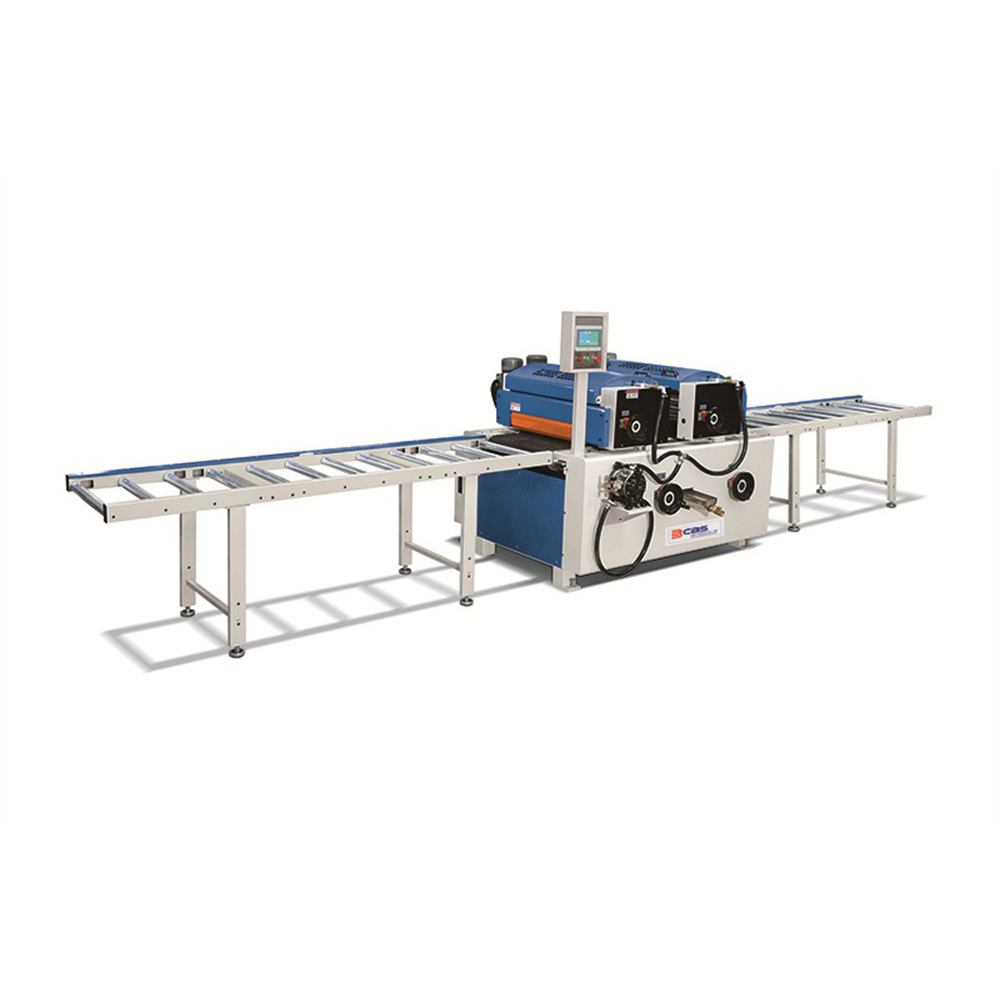

Aluminium Formwork Stiffeners Chamfer Cutting Ma...

-

Aluminium Formwork Single Head Slot Milling Mac...

-

Mochini o le Mong oa ho Seha Hlooho o nang le Digital Measur...

-

Mochini oa ho kuta oa CNC Hydraulic Guillotine

-

CNC Aluminium Profile Variable Angle Double Mit...

-

Mochini oa Lacquering oa Roller o Iketselitseng